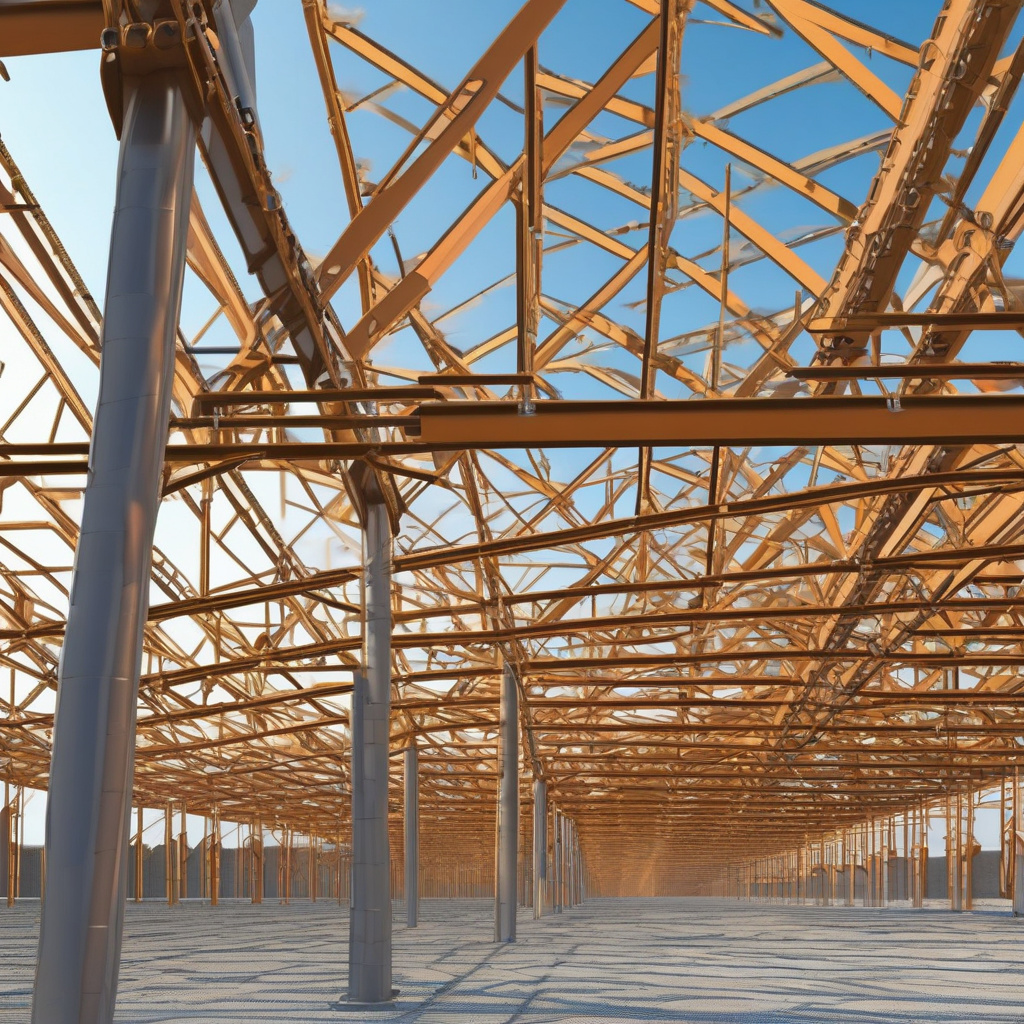

Trusses made of profile pipes have become a cornerstone in modern architectural design, providing robust solutions for various DIY enthusiasts and professional builders. Whether you’re renovating your home or redesigning an industrial space, understanding the intricacies of truss calculation and how to manufacture them yourself is essential. Let’s delve into the art and science behind creating these structural marvels, ensuring your project stands tall and proud like an architectural masterpiece.

The Basics of Truss Design

Understanding trusses made of profile pipes starts with the basics of truss design. This crucial component serves as the backbone of roofs and bridges, distributing loads efficiently while providing stability. When planning to build trusses, it’s vital to comprehend the mechanics of load distribution, material choice, and the architectural appeal.

Trusses can vary in design complexity, from simple triangular shapes to more elaborate structures. Each style offers specific advantages, dependent on the intended use. With precise calculation, trusses ensure that architectural endeavors do not merely stand the test of time but also withstand environmental stresses.

The design process involves selecting the right profile pipe, a hollow section that merges strength with lightweight properties. Material choice often hinges on factors such as weather resistance, durability, and ease of maintenance. As you delve into DIY manufacturing, consider the project’s unique demands and the specific conditions your truss will face.

For those venturing into DIY construction or professional projects, it’s vital to incorporate tried-and-tested design principles. Effective planning and blueprinting will guide the execution process, promising both safety and aesthetic appeal.

Fact: A standard triangular truss design can distribute loads with remarkable efficiency, making it a preferred choice across various construction projects.

- Choose the right truss type for your project.

- Accurately measure all dimensions beforehand.

- Consider local climate and environmental conditions.

- Consult existing building codes and regulations.

- Always prioritize safety in your design.

Calculating Profile Pipe Trusses

Calculating trusses made of profile pipes requires a keen understanding of load dynamics and structural geometry. The process involves determining the forces acting on the truss, which will influence material selection and design configuration. Proper calculation ensures both safety and cost-effectiveness.

Various tools and software are available to assist with accurate calculations. These resources factor in the truss span, load requirements, and pipe specifications. By leveraging these modern tools, you can minimize errors and optimize your design for efficiency.

It’s crucial to integrate design codes and regulatory standards during your calculations. These codes ensure that your truss can bear anticipated loads while adhering to safety norms. Incorporating industry standards into your calculations delivers peace of mind and enhances structural integrity.

Beyond basic calculations, consider exploring deeper into finite element analysis or consulting with structural engineers for more complex projects. This additional step ensures your design is both innovative and reliable.

Tip: Use design software to simulate different load scenarios to fine-tune your truss design for optimal performance.

- Identify the truss’s intended load capacity.

- Choose appropriate design and material.

- Utilize reliable truss calculation software.

- Incorporate safety margins in your calculations.

- Verify your design with industry standards.

DIY Manufacturing of Profile Pipe Trusses

Taking on the task of DIY manufacturing trusses made from profile pipes is not for the faint-hearted, yet it’s incredibly rewarding. With the right guidance, you can craft a structural wonder right in your backyard. Begin by gathering essential tools and materials, including an array of profile pipes, connectors, welding equipment, and safety gear.

Precision is key. Accurate cutting and welding of pipes are fundamental to ensuring a sturdy framework. It’s crucial to ensure all joints are firm and secure, as even the slightest inconsistency can compromise the entire structure.

The assembly process demands patience and precision. Take the time to carefully align each piece, welding joints seamlessly for a robust structure. Employing jigs can assist in maintaining consistency throughout the assembly process.

Once constructed, inspect the truss for any potential weaknesses or flaws. Conduct load testing to validate your design and guarantee its readiness for installation. Remember, a well-built truss epitomizes durability and style.

Statistic: DIY manufacturing of trusses can save up to 30% on construction costs compared to purchasing ready-made options.

- Plan your project with detailed drawings.

- Use jigs to ensure accurate alignment.

- Conduct weld inspections for structural integrity.

- Perform load tests to verify robustness.

- Adopt safety gear to protect during the build.

Essential Materials and Tools

The success of building trusses made of profile pipes hinges on the materials and tools employed. Profile pipes boast versatility and strength, serving as ideal choices for structural components. It’s essential to invest in quality materials to guarantee lasting results.

Apart from profile pipes, welding equipment is paramount in your toolkit. Choose a welding apparatus suitable for the material’s thickness and the environment in which it will be employed. Personal protective equipment (PPE) for welding includes gloves, goggles, and welding helmets to safeguard against hazards.

Other tools include measurement devices, cutting tools, and assembly jigs. These instruments streamline the construction process, promoting both accuracy and efficiency. Prioritize investing in reliable brands known for their durability and performance.

Incorporating high-quality materials and tools lays the groundwork for a successful DIY truss endeavor. Remember that the choices you make at this stage significantly influence the final product’s quality and performance.

| Material/Tool | Purpose | Characteristics |

|---|---|---|

| Profile Pipes | Primary structural element | Strong, lightweight, corrosion-resistant |

| Welding Equipment | Joining metal components | Varies by application, needs appropriate PPE |

| Measurement Tools | Ensuring precise dimensions | Essential for alignment and accuracy |

| Jigs | Consistent assembly | Facilitates uniformity |

- Invest in premium quality profile pipes.

- Equip yourself with reliable welding tools.

- Essential PPE includes gloves and goggles.

- Ensure precise measurement with accurate tools.

- Utilize jigs for consistent results.

Ensuring Structural Integrity and Safety

When constructing trusses made of profile pipes, ensuring structural integrity and safety is paramount. The success of any construction project rides on the promise of safety and resilience. Employ stringent quality control measures throughout the manufacturing process to detect and rectify any flaws early.

Every stage, from design and calculation to assembly, must align with established safety standards and engineering guidelines. Employ additional checks and balances, including load-bearing tests, to validate your truss’s strength. Documentation of safety practices should be readily accessible for reference.

Remember, a truss’s appearance doesn’t always convey its reliability. Prioritize function over form, ensuring each component contributes to the overall structural integrity. Assess each joint and connection meticulously to minimize future risks.

Lastly, regular maintenance and inspections can extend your truss’s lifespan while safeguarding against unforeseen failures. Through proactive measures, your truss can weather any storm, remaining a dependable cornerstone of your construction project.

Sun under the roof: how to choose the perfect windows for the attic?

11 types of roofs for private houses: features, advantages and choice

Installing an antenna on the roof: practical and legal aspects of the decision

roof repair los angeles

FAQ

What are the advantages of using profile pipes for trusses?

Profile pipes offer several benefits when used in truss construction. Firstly, they provide a high strength-to-weight ratio, making trusses both strong and lightweight. This property is particularly useful in large-span constructions where structural weight needs to be minimized to reduce the load on supporting elements. Moreover, profile pipes have a uniform geometry, which ensures an even distribution of stress across the structure, enhancing its durability and stability. Another advantage is the versatility in design; profile pipes can be cut and welded into various configurations, catering to both standard and custom structural requirements. They are also more resistant to torsion compared to other shapes, helping maintain structural integrity under various loads. Finally, the surface of profile pipes is often smooth and suitable for aesthetic applications, allowing them to be utilized effectively in visible structures.

How do you calculate the load-bearing capacity of a truss made from profile pipes?

Calculating the load-bearing capacity of a truss made from profile pipes involves a few key steps. Initially, you need to identify the specific loads the truss will encounter, such as dead loads (the weight of the truss itself and any permanent attachments), live loads (variable weights such as people, furniture, or snow), and environmental factors like wind or earthquakes. Next, select the type and size of profile pipe based on these loads, considering the material’s yield strength and safety factors. Utilization of specialized structural analysis software or methods such as Finite Element Analysis (FEA) can provide precise stress distribution, ensuring the loads are properly managed throughout the truss. Additionally, the design should incorporate safety factors to account for unexpected loads and variances in material properties. By understanding both the loads and the structural capacity of the selected profile pipes, an effective and safe truss design can be crafted.

What tools are needed for the do-it-yourself manufacturing of profile pipe trusses?

Embarking on a DIY project for manufacturing trusses from profile pipes requires a set of specific tools to ensure precision and safety. Essential tools include a metal cutting saw or angle grinder for trimming the pipes to the necessary lengths and angles. A welding machine is crucial for joining the pipes securely at the joints, ensuring structural integrity. It’s advisable to use a jig or a fixture to hold the pipes in place during welding, maintaining accuracy in alignment and angles. Additionally, a tape measure and square will aid in precise measurement and alignment before cutting and assembling the truss. Personal protective equipment (PPE) like safety glasses, gloves, and a welding helmet are vital for safe operation. A set of clamps can also be handy to hold elements together during welding and any other adjustment process. A detailed plan and schematic of the truss design should guide the entire process, ensuring that all components are fabricated correctly and to the required specifications.

What common mistakes should be avoided during the design and manufacturing of profile pipe trusses?

When designing and manufacturing profile pipe trusses, several common mistakes should be meticulously avoided to ensure structural soundness. A frequent error is the neglect of accurate load calculations, which can lead to a truss that is either over-engineered, resulting in unnecessary cost and weight, or under-engineered, posing a risk of structural failure. Another mistake is improper alignment during welding, which can compromise the truss’s integrity and lead to misalignment issues when joining with other structural elements. Inadequate or incomplete welding is also a frequent pitfall that can cause joint failures. Not accounting for environmental factors, such as corrosion, particularly in outdoor settings, can lead to premature degradation of the truss. Using incorrect materials or pipe sizes without verifying their suitability for the specific application is another critical oversight. Each of these mistakes can be mitigated with thorough planning, precise calculations, proper tool use, and adherence to engineering standards and guidelines. Regular inspection and maintenance routines should also be established to ensure the long-term performance and safety of the trusses.

“`