Creating a foam cutting machine is becoming the latest DIY trend amongst homeowners passionate about crafting, interior design, and practical renovations. As the sunlight dances across the rooftops of Los Angeles, many find themselves inspired by the unique architectural landscape. From the undulating Hollywood hills to the structured charisma of mid-century modern homes, the emphasis on customization has never been more pronounced. For those daring enough to try their hand at creating their own foam cutting apparatus, the rewards are multifold: affordability, control, and pride in craftsmanship.

Brief summary: Building a foam cutting machine is a practical and cost-efficient solution for DIY enthusiasts looking to personalize their home renovations. This guide explores effective methods, expert tips, potential pitfalls, and tangible benefits for tackling foam-based projects, drawing insights from real-life remodeling experiences in Los Angeles.

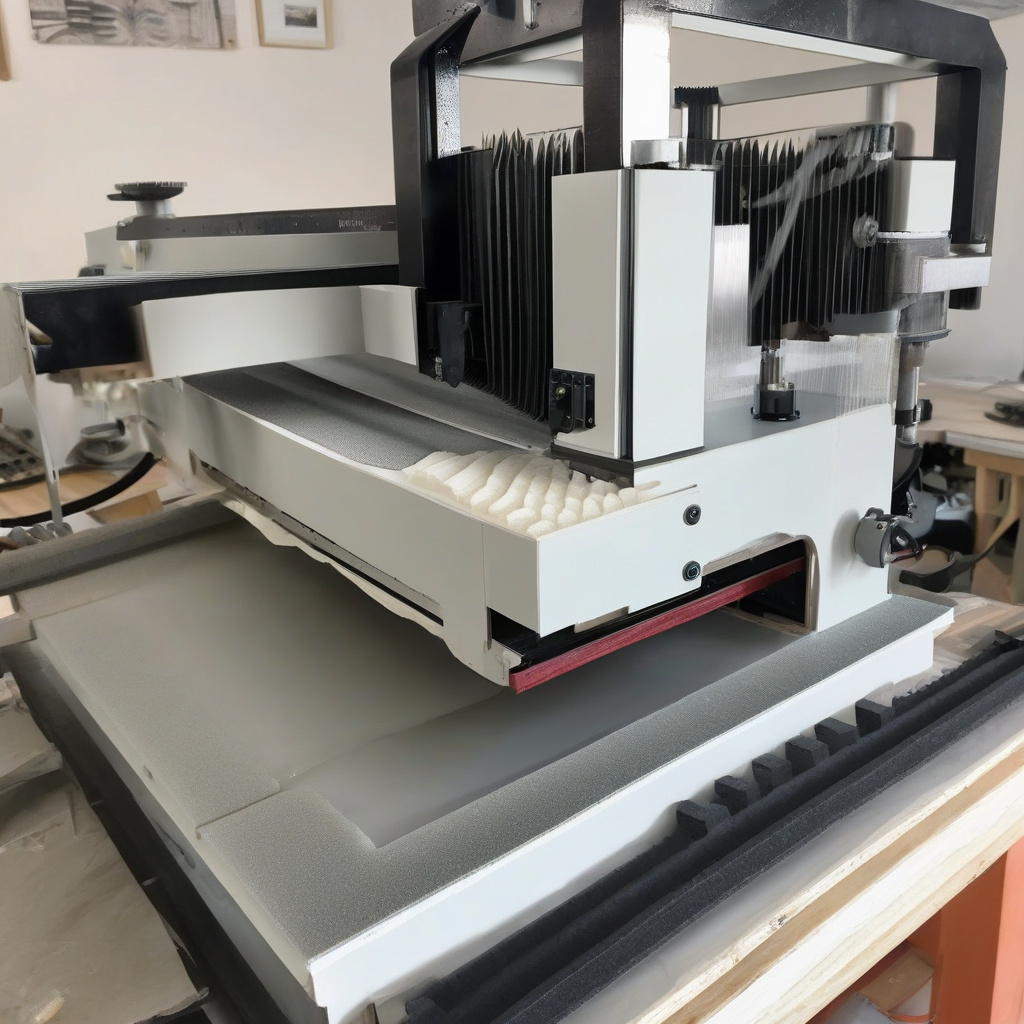

Why Foam Cutting Machines Matter in DIY Projects

Foam cutting machines are versatile tools essential for various DIY projects. Whether you’re crafting a custom headboard or insulating a new playroom, the precision they offer is unmatched. Unlike traditional cutting methods, these machines ensure clean edges and minimal material wastage, making them a favorite for those focused on sustainability. This precision not only saves resources but also enhances the overall aesthetic appeal of the finished product, a crucial factor in style-conscious cities like Los Angeles. As many local homeowners notice, the ability to tailor-cut materials can transform a basic renovation into a bespoke masterpiece.

Moreover, owning a foam cutting machine offers the dual advantage of functionality and flexibility. Unlike outsourcing the job, having your machine means immediate access whenever a creative urge strikes. This accessibility empowers DIYers to experiment with infinite designs without the pressure of tight deadlines or additional costs. Moreover, the learning curve is not as steep as one might imagine, with tutorials readily available online, coupled with a hearty spirit and a garage, transformation is but a weekend away.

Cost-saving is yet another compelling reason to consider a DIY approach. While professional foam cutting services can be pricey, building your machine can be relatively inexpensive, depending on the features you’re after. By crafting it yourself, you take control over your project’s budget and outcome, directing your hard-earned dollars into the area’s most impactful improvements.

In summary, if you’re contemplating a new endeavor into the world of home improvement or simply wish to hone your crafting skills, a foam cutting machine could be the cornerstone of your next project, effortlessly bridging ambition and ability.

What You Should Know About Building Your Foam Cutter

Building a foam cutting machine isn’t as daunting as it may sound. The primary components include a power supply unit, a Nichrome wire for cutting, and a frame to hold everything together. When considering the power supply, aim for something adjustable—it offers flexibility with different foam densities and thicknesses. The cutting wire, typically Nichrome, needs to be of top quality for efficient heating and precision.

One critical factor is to construct a sturdy and ergonomic frame. A stable frame reduces vibrations and ensures the wire remains taut, boosting accuracy and ease of use. Materials like wood or aluminum are often preferred for their durability and ease of manipulation. The construction process, although intricate, is a thrilling puzzle where each piece contributes to a more holistic home renovation experience.

Consider Safety and Maintenance

Safety should never be underestimated. Nichrome wires heat up to high temperatures and can cause burns or fires if mishandled. Always ensure safety goggles and gloves are part of your essential kit. Maintenance, too, plays a vital role. Regularly checking wire tension and ensuring connections are secure will prolong your machine’s life and efficiency, making future projects a breeze rather than a burden.

For many Angelenos, this hands-on engagement harkens back to a simpler time when manual craftsmanship reigned supreme. Embracing such a mindset could see your home transcend beyond structure, becoming a canvas for expression instead. As long as construction meets the basic safety standards, the sky truly is the limit!

In conclusion, as with any DIY endeavor, patience, preparation, and practical knowledge are your strongest allies. This knowledge empowers creators, allowing them to explore new renovation territories previously thought inaccessible, with that familiar Southern California sun as their muse.

Deciphering the Design Options and Possibilities

Design possibilities with a foam cutting machine are practically limitless. Whether tackling thermoplastic sheets for model architecture or creating intricate wall panels, the flexibility of foam allows for remodeling opportunities that other materials might restrict. This versatility is particularly significant in Los Angeles, where home personalization is prized, and where space can constrict traditional landscaping options.

With foam, one can outline anything from delicate floral motifs to bold geometric patterns with ease, enhancing both interior and exterior spaces. Many have found that foam designs can seamlessly complement metal siding installations adding texture and depth without overshadowing existing aesthetics. This blend of functionality and form has become a signature feature of modern homes, tailored by those who dare to dream differently.

Cost-Effectiveness and Innovation

The creativity unleashed through foam is astounding. For a city that thrives on innovation, from tech startups to entertainment, such tools offer aspiring designers a playground of possibilities. In recent projects, Los Angeles architects have incorporated foam into ornamental moldings and detailed component designs, offering a fresh take on more conventional materials.

To summarize, foam is both forgiving and flexible, serving as a canvas where imagination and reality meet to thrive. As many home improvement enthusiasts in Los Angeles will attest, it’s not merely about building a structure—it’s about creating a sanctuary that tells your unique story.

| Method | Cost | Material Flexibility | Skill Level Required |

|---|---|---|---|

| DIY Foam Cutter | Low to Medium | High | Intermediate |

| Pre-built Foam Cutter | High | Medium | Beginner |

How to Transform Your Ideas Into Reality

The journey from concept to completion is inherently satisfying, especially for projects driven by personal touch. The process typically begins with sketching your design ideas. From furniture to ornamental art pieces, the type of item determines the thickness and density of foam required.

Once your designs are finalized, proceed with transferring your sketches onto the foam. Cutting follows—a process both thrilling and precise with the right tools. Throughout Los Angeles, the marriage of innovation and design is visible in myriad ways, not least in high-end spaces where foam serves as the unlikely hero.

After cutting, assembly is where creativity truly comes alive. Depending on your project, this can involve anything from simply gluing pieces together to more complex techniques like embedding lighting features or custom window sections. These projects resonate due to their simplicity and sophistication, creating spaces that feel as good as they look.

Step-by-Step: Building Your Foam Cutter

Start by sourcing the essential components, including the power supply, Nichrome wire, and frame. Assemble the frame securely before attaching the wire. Connect the power supply, ensuring stable and secure connections to avoid electrical hazards.

Test your setup by cutting a small foam piece to ensure everything functions correctly. Adjust as necessary for smoother operation. Personalize the machine with enhancements like adjustable wire tension or differing frame sizes for expanded utility. From analyzing frameworks to layering textures, let each project be a testimony to your evolving skillset.

When It Makes Sense to DIY: Foam Cutter Edition

Embarking on a DIY project such as a foam cutting machine makes sense under specific circumstances. Foremost is the desire for customization. For homeowners who love tinkering and personalizing their surroundings, a DIY route is an invitation to merge creative impulses with structural projects. Similarly, those looking for cost-effective alternatives without sacrificing quality will find this endeavor particularly rewarding.

Moreover, by working on such projects, homeowners gain insights into construction techniques that are often overlooked when hiring professionals. The hands-on experience equips you with the knowledge and confidence to tackle further complex projects, be it installing new custom brickwork or reimagining backyard landscapes. As a result, some find joy not simply in the end result but in the process, reveling in the very act of creation.

A study conducted by the American Society for Interior Designers highlights that 88% of DIYers gain increased satisfaction from projects over prefabricated solutions, emphasizing the joy derived from creative control.

Conclusively, a DIY foam cutting machine caters to audiences disinterested in mediocrity; it caters to artists, architects, and dreamers alike. For those lazing on a Monday afternoon in their sun-drenched Los Angeles home, the reminder that they built their cozy haven with their own two hands offers unrivaled contentment.

Foam cutting machines serve as an example of the rising trend in DIY that combines affordability and customization. Embracing self-help projects aligns with a broader movement towards personalized living spaces.

Risks vs. Opportunities

As with any venture, a balanced view of the risks involved alongside potential benefits is essential. Risks include initial setup challenges, potential safety hazards if mishandled, and the possibility of initial frustration during the learning phase. However, these are easily mitigated with adequate precautions and perseverance.

Opportunities, on the other hand, are vast. Gaining expertise in a versatile skill can lead to not only cost savings but also the realization of personalized renovation projects far beyond initial ideas. Moreover, the satisfaction derived from engaging with your home at such an intimate level is, indeed, priceless.

After examining both sides, it becomes apparent that the opportunities surpass the nominal risks for most determined DIY enthusiasts. As one oversees their progress, there’s an implicit empowerment, a connection between self and space, making the home not just a shelter but a statement.

“In the race for customization, DIY has emerged not only as a cost-saving measure but as a cultural phenomenon promoting hands-on engagement and personal expression in home design,” remarks local architect Lisa Anselmo.

Foam Cutting: The Los Angeles Remodeling Scene

To immerse oneself in the Los Angeles remodeling scene is to step into a world where tradition and innovation collide in a harmonious dance. In this metropolis, the artistry of architecture and the splendor of home design elevate everyday living into an experience. Foam cutting, with its capacity to inspire unique renovations, fits into this vibrant mosaic seamlessly, offering a strategy for those yearning to infuse their environments with personal flair.

As the renaissance of mindful renovation takes hold, more residents are embracing the initiative to stylize their living spaces personally. The flexibility offered by foam as a medium enables everything from ethereal cloud ceilings to stealthy soundproofing barriers hidden within walls, further proving its indispensability in contemporary design

The sustained popularity of DIY projects, particularly foam-based craftsmanship, illustrates Angelenos’ adaptive and innovative spirit. With a foam cutting machine at your disposal, the tight balance between functionality and aesthetics that epitomizes Los Angeles architecture is close within reach.

Therefore, the journey of crafting a foam cutting machine is far greater than mere tool creation—it’s a step toward mastering the art of personalized living, in tune with the rhythm of Los Angeles living. Engage, create, and cherish, for within these crafts lies the true essence of home.

- Foam cutting machines offer precision and customization crucial for DIY home projects.

- Building your machine can save costs and allow personalized redesigns.

- The process increases satisfaction through creative control.

- Consider safety and maintenance as integral elements of DIY projects.

- Foam’s versatility makes it a staple in Los Angeles renovations.

“`html

FAQ

What is a foam cutting machine, and how does it work?

A foam cutting machine is a tool used to slice through foam materials with precision. In practical terms, it works by heating a wire to a temperature capable of melting through foam smoothly, avoiding frayed edges. In many renovation projects, professionals use these machines to create custom foam shapes for insulation or decorative details. By integrating a simple heating element and tensioned wire, these machines ensure that cuts are clean and detailed. For those who enjoy DIY projects, making your own machine can be a cost-effective solution, while providing an opportunity to customize your cuts according to specific project needs.

How can I build my own foam cutting machine at home?

Building a foam cutting machine at home involves a few essential components: a frame to hold your cutting wire, a power source to heat the wire, and tension adjustments. In DIY settings, many opt for nichrome wire due to its durability under high temperatures. You’d start by constructing a stable base using wood or metal. Then, secure the wire with a tension system, such as springs, to keep it taut. Lastly, connect a power supply like a battery or transformer that can adjust voltage. Many in this field emphasize starting with a small prototype to refine your design skills before tackling larger projects. A practical tip is to test with scrap foam first to master speed and pressure.

When does creating your own foam cutting machine make sense?

Creating your own foam cutting machine is ideal when personalized cuts are frequently needed, especially during extensive remodeling where foam insulation or decorative elements are utilized. In single-family homes undergoing transformation, bespoke foam shapes can fit unusual nooks or aesthetic concepts. Many homeowners find this DIY route not only cost-effective but also invaluable for learning precise cutting techniques. It’s particularly advantageous when standard machines are either too costly or do not meet your specific cutting requirements. Knowing exactly what you need can save both time and future modification expenses.

What are common mistakes to avoid when making a foam cutting machine?

A frequent pitfall in DIY foam cutting machines is overheating the wire, which can lead to inconsistent cuts and wire burnout. Many enthusiasts often overlook the importance of a reliable tension system, resulting in sagging wires that cause jagged edges. Moreover, inadequate power supply considerations can yield a machine that is either underpowered or unsafe. It’s crucial to source high-quality materials, understanding that while nichrome wire seems trivial in dimension, its resistance properties are fundamental to dependability. Regular testing and adjustments during the assembly phase can mitigate these risks, ensuring a machine that delivers both safety and performance.

What are the cost considerations when constructing a DIY foam cutting machine?

Constructing a DIY foam cutting machine is often more economical than purchasing a commercial model. Key expenses involve materials such as nichrome wire, a power source, and a sturdy frame, all of which can be sourced at local hardware stores or online markets. The savings are especially apparent when scale and specialized cuts are necessary, as pre-built machines can be prohibitively expensive. However, keep in mind that potential costs arise if incorrect materials or setups necessitate replacements. Many experienced hobbyists suggest budgeting for trial and error, thereby avoiding the surprise of unplanned expenses.

What are the pros and cons of making your foam cutting machine?

Crafting your foam cutting machine presents numerous benefits: customization, cost efficiency, and a fulfilling DIY experience. You’re in control of design specifications, which allows adaptations to fit unique project requirements. Many home renovators, particularly in California where innovation is prized, find immense satisfaction in tailoring tools to fit exacting standards. On the downside, the process demands ample time and testing, with a learning curve that can be steep for those unfamiliar with electrical components. Balancing creativity with practicality is often key, understanding that initial setups might not achieve commercial consistency immediately. For personalized advice, consider reaching out to a local renovation consultant, such as through this [page to connect with nearby experts](https://californiarenovation.top/contact/).

How does maintenance of a DIY foam cutting machine typically proceed?

Maintaining a DIY foam cutting machine involves regular inspections for wear and mechanical integrity. Tension wires should be checked to ensure they remain taut and free from corrosion, a problem particularly in coastal areas like parts of California. Regularly clean the cutting line to prevent foam residue build-up, which can skew future cuts. Electrical connections should also be revisited periodically to rule out any potential shorts or frayed wiring. In practice, frequent users find periodic evaluations mitigate larger repairs, maintaining machine efficacy over the long term. Documenting issues in a maintenance log can help troubleshoot recurring problems swiftly.

What limitations should you be aware of with DIY foam cutting machines?

Though building a DIY foam cutting machine provides distinct advantages, it comes with limitations such as precision constraints and power dependency. For those not versed in electrical engineering, managing heat generation without overcapacity leads can be challenging. Another notable limitation is the consistency of cuts, where manual setups may lack the repeatability found in commercial models. This is something particularly crucial for professional applications where exact replication is mandatory. Yet, these challenges can be minimized with practice and experimentation, and many enthusiasts enjoy the iterative improvement process that a DIY setup demands.

“`