In the sprawling urban landscape of Los Angeles, where dreams are constructed one beam and plaster at a time, the never-ending quest for the perfect waterproofing method for homes and commercial buildings turns backyard conversations into debates akin to a courtroom drama. Los Angeles residents, whether they own a cozy bungalow in Silver Lake or a modern masterpiece in the hills of Hollywood, find themselves tangled in talks about liquid rubber for waterproofing—a seemingly magical solution stirring curiosity, skepticism, and investment in equal measure.

Brief summary: Liquid rubber is gaining popularity as a waterproofing solution in Los Angeles due to its durability and flexibility. This article delves into its applications, effectiveness through real user reviews, and compares it with other methods. Homeowners and builders are urged to consider the material’s benefits and drawbacks in their renovation projects.

What you should know about Liquid Rubber for Waterproofing

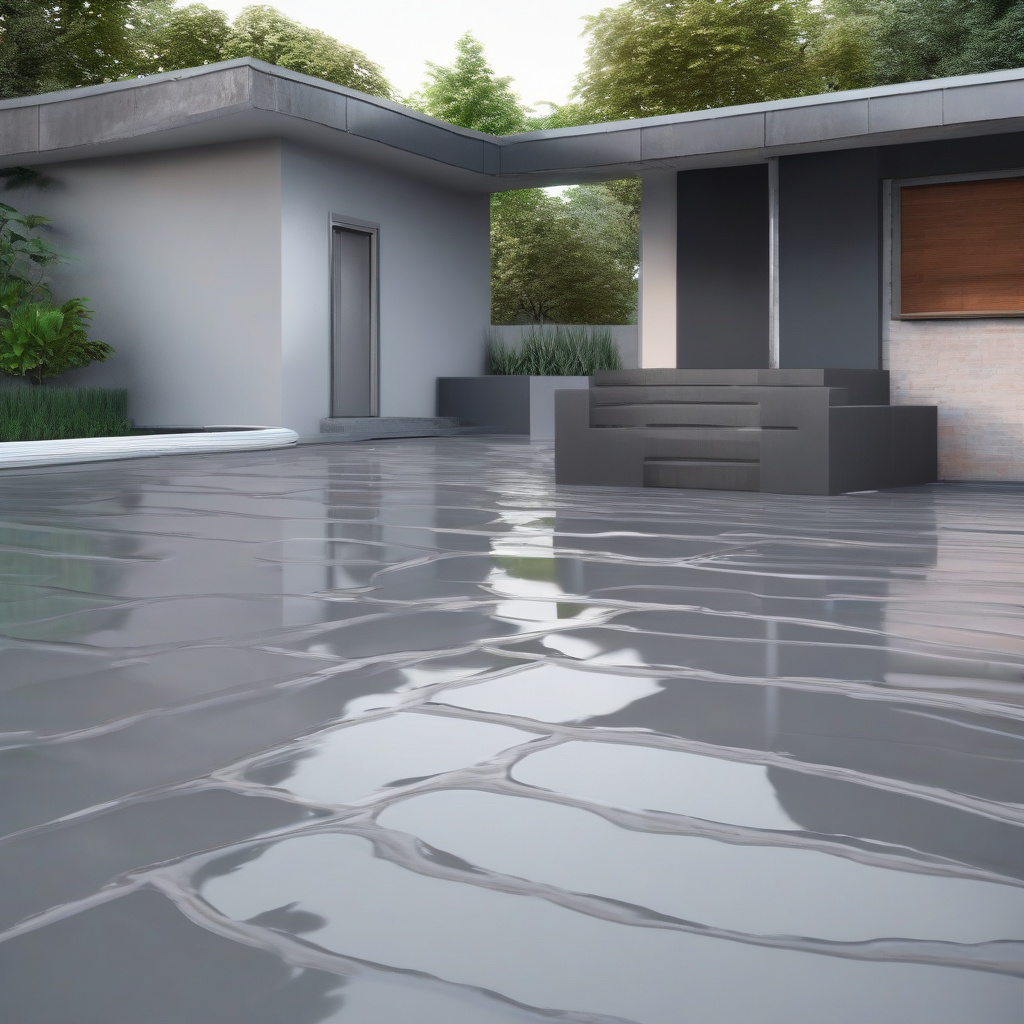

Liquid rubber has come a long way from its initial use in repairing rooftops for commercial buildings. Today, its application is as diverse as the Los Angeles skyline. This versatile polymer is sprayed or painted onto surfaces, creating a seamless barrier that stands between your home and the malicious Californian weather.

Homeowners are thrilled by how liquid rubber molds to any surface, be it wood, concrete, or metal. It forms a flexible, yet sturdy layer impervious to water, making it a darling among those who’ve had to deal with notorious roof leaks. While not the cheapest solution, many argue it’s the most effective.

Despite its laudable qualities, liquid rubber doesn’t escape criticism. Skeptics argue about its performance longevity—a concern magnified by horror stories of incorrect application leading to immense repair costs. Proper installation is paramount, as with any high-stakes construction challenge.

As more Los Angeles homes undergo renovations, the chatter echoes back: is investing in liquid rubber a wise decision, or is it simply a shiny trend that will gloss over actual issues? The answer rests, as always, in the hands of experienced contractors willing to do the homework.

“Nine out of ten contractors reported that silicone-based waterproofing materials outlast traditional tar-based ones in regionally variable climates.” — Construction Safety Journal

How Liquid Rubber Compares with Other Waterproofing Solutions

When stacked up against myriad options like bituminous coatings, polyurethane, and sheet waterproofing, liquid rubber stands out by virtue of its ease of application and environmental friendliness. Homeowners inclined towards green solutions often find themselves gravitating towards this material.

The competitive landscape needs clearer understanding—let’s sidestep into a comparative glance. Consider the spectrum of waterproofing options available to Los Angeles’ urban adventurers, particularly those who have delved into how roofing connects to chimneys without allowing leaks. The liquid rubber’s ability to integrate seamlessly is often unmatched.

According to experts, alternative methods have their own set of merits. For instance, bituminous coatings—a traditional choice—remain popular for their cost-effectiveness, yet they grapple with longevity concerns. Polyurethane, meanwhile, excels in elasticity but often falters in extreme heat conditions prevalent in the city.

For the well-informed homeowner, the decision rests on weighing personal priorities: longevity versus ease, cost versus flexibility. The endgame, invariably, embraces the nuanced dance between modern technology and architectural wisdom.

| Waterproofing Method | Durability | Cost | Ease of Application |

|---|---|---|---|

| Liquid Rubber | High | Moderate to High | Simple |

| Bituminous Coating | Moderate | Low | Complex |

| Polyurethane | High | High | Moderate |

Exploring Real-life Reviews: The Residents’ Verdict

No thorough exploration can be complete without considering the voices of those who live amidst the ongoing renovation cyclone. Homeowners all across Los Angeles have taken to social platforms and renovation forums, either singing praises or casting doubts on liquid rubber’s effectiveness.

Review excerpts reveal a trend: the general satisfaction from those who’ve adhered strictly to recommended application methods is noticeably high. Patience and precision during installation reap long-lasting rewards, as many claimed, including those who experimented with different materials before settling on liquid rubber.

This isn’t to downplay the voices of dissent. Some users lament premature peeling and cracks when incorrect substrates were used without proper primers or sealants. In rogue cases, improper rooftop preparations resulted in leakages, causing frustration and mistrust.

So, as tales from the LA neighborhoods confirm, the key to reaping liquid rubber’s benefits lies not simply in purchase but in strategic, informed application. The word on the street remains clear—hire reputable professionals for commercial paving projects, and don’t scrooge on quality.

When it Makes Sense to Choose Liquid Rubber

Timing—and timing in Los Angeles construction is an art unto itself. For those embattled with persistent wet patches in the middle of a blazing summer, liquid rubber arrives as a hero crafted by foresight and flexibility. If leaky basements or suspect drainage persists irrespective of basic waterproofing measures, it’s time to consider the liquid path.

The decision’s impetus lies in acknowledging the material’s weather resistance and its virtue of malleability—a rare combination many Angelinos regard as a game-changer, especially in an earthquake-prone region. Distinct geographical conditions and the varying terrain challenge traditional solutions, making liquid adaptability a foremost choice for many.

Deliberations on various primers can further fine-tune the effectiveness of liquid rubber. When partnered with complementary materials, the outcomes can be amplified manifold, echoing satisfaction across neighborhoods once marred by water travails.

Nevertheless, understanding the fundamentals of construction juxtaposed with environmental conditions makes opting for liquid rubber not just a choice but a savvy solution when aligned with foresight. The proximity of the flawless weather shield and your roof awaits the calculated decision.

“Liquid polymers are 300% more flexible than traditional waterproofing membranes, minimizing crack formation.” — Material Science Annual Report

Understanding the Installation Process — A Practical Guide

Picture it: your roof primed and ready to bind with liquid rubber’s ethereal embrace. Yet, the entire beauty of liquid rubber lies in precise application—a dance between readiness and patience. Let’s wade through a practical approach on how to secure your surfaces effectively.

Start with a clean slate—ensuring the surface is devoid of dirt, oil, and loose fragments. The result? A perfect marriage where rubber adheres like ink to parchment. Delve into smart design considerations to ensure no pairing goes wasted when marrying different construction panel types.

The second step is layering with ease. With either a brush or a sprayer, especially for the large swathes of rooftop, apply evenly while keeping an eye on uniformity. This method ensures solid coverage without dreary overspending.

Progressively, each coat must dry thoroughly, a step often hurried by the overzealous but unwise. A requisite pause lets liquid polymer breathe and rest, intended to gift you a perfect barrier against the elements.

Finally, embrace legacy maintenance: periodically reassess and amply touch upon this once unattainable dream. With timely upkeep, an everlasting shield of liquid rubber becomes your house’s undying defense against LA’s many meteorological tantrums.

“Proper maintenance of newly applied waterproofing layers can extend lifespan by up to ten years.” — Home Renovation Guide

Concluding Thoughts: Navigating the Path to an Improved Home

As renovations galore buzz Los Angeles with energy, and materials like liquid rubber flaunt efficiency, the underlying narratives of both potential and caution permeate. Inidal impressions influence choices; yet, considered assessments cut through hype, anchoring sustainability and functionality.

It’s worth reiterating the cautionary investor’s tale amidst the excitement—a stitch in time saves nine. Converting homes into weatherproof havens doesn’t restrict itself to liquid rubber alone but rather to the holistically nurtured understanding of materials, processes, and possibilities.

Engaging with local expertise, like experts in roof improvements, turns insightful decisions into routine reality. Of course, there’s plenty more to consider in this ever-changing field. Taking a step back to envision the larger picture often defines the striking difference between a mere structure and the conferred title of “home.”

- Liquid rubber is preferred for its flexibility and seamless application.

- Proper installation is critical to success, ensuring longevity.

- User reviews highlight varied experiences, emphasizing professional help.

- Environmental conditions in LA favor adaptable solutions like liquid rubber.

- Maintenance enhances the durability of waterproofing efforts.

FAQ

What is liquid rubber, and why is it used for waterproofing?

Liquid rubber is a bituminous membrane known for its exceptional waterproofing capabilities. In real renovation projects, it often becomes apparent that maintaining the tight seal over time is crucial. Homeowners in places like California, where rainy seasons can affect water exposure, appreciate its seamless application, which ensures no weak points for water leakage. Many experts point out that the versatility of liquid rubber, whether on flat roofs or around foundations, provides an adaptable solution that is both applied easily and flexible enough to accommodate structural movements without cracking.

How do I choose the right type of liquid rubber for my home?

Selection often depends on the specific needs of your project. In older properties undergoing renovation, it’s crucial to consider the existing building materials and any peculiarities in the structure. Many brands offer formulations tailored for different surfaces — ensuring compatibility is key. Homeowners frequently underestimate this aspect, assuming one product fits all purposes. Ask a professional for advice, or, for tailored guidance, reach out to experienced consultants, and they can help ensure the product meets your home’s specific challenges and environmental conditions.

When is liquid rubber not the best option for waterproofing?

While liquid rubber is versatile, it’s not ideal for every scenario. In newer builds with modern systems, some components may fare better with specialized water barriers. For instance, metal roofing may require specific adhesives for bonding purposes where rubber might fail to adhere correctly. Furthermore, in extreme cold climates, installation might pose challenges due to the cure time required. It’s important to assess if your specific situation aligns with these scenarios, consulting guidance from a reliable local contractor or service provider when necessary.

What are the common mistakes people make when applying liquid rubber?

A typical mistake is not preparing the surface adequately before application. In real-world scenarios, ensuring the area is clean, dry, and free of dust and debris is often overlooked. Skipping this crucial step can lead to poor adhesion and eventual water seepage. Additionally, applying the product too thickly can cause it to crack once cured, defeating its purpose. A practical tip is to apply in multiple thin layers, allowing adequate drying time between coats to ensure a robust, long-lasting finish.

What are the cost considerations when using liquid rubber for waterproofing?

Cost is a critical factor that can vary widely based on project size and specific material needs. Many homeowners find that while the upfront expense can be higher than traditional coatings, the longevity and reduced maintenance costs balance this investment over time. Calculating the total area requiring coating and comparing it to product coverage rates is advisable. Also, factor in the potential need for professional labor if DIY application isn’t practical. Always compare this with the costs of repairing water damage should improper materials or installation be chosen.

What are the benefits and drawbacks of using liquid rubber?

Liquid rubber’s benefits include its flexibility and seamless, protective coating, which adapts to surface irregularities. It adheres to most surfaces, providing excellent resistance against UV rays and chemical corrosion. However, some drawbacks are its sensitivity to certain weather conditions during application and the necessary precision in ensuring ample curing time. In practical home renovation, balancing these factors is key to deciding when and where it is the ideal choice. Proper research and consultation can mitigate these potential negatives.

How should liquid rubber be maintained after application?

Maintenance for liquid rubber applications is generally minimal, as it is designed for durability. However, regular inspections are advisable, especially after severe weather conditions. If your home is in a heavily shaded area, thereby more prone to mold or mildew, a gentle annual cleaning with a non-abrasive brush and a soapy water solution may be beneficial. Address any signs of damage or wear promptly to prolong the membrane’s effectiveness. This proactive approach can catch minor issues before they grow into major problems.

Where can homeowners find expert advice on liquid rubber application?

For homeowners seeking expert advice on liquid rubber application, reaching out to local renovation specialists is wise. Visiting [this experienced contact page](https://californiarenovation.top/contact/) is a great start, offering personalized consultations that ensure your project’s success. They provide insights tailored to your specific needs and environmental conditions in California, highlighting a wealth of regional expertise. Whether considering application or looking to remedy an issue, contacting these professionals ensures accessible, solid guidance.