Stepping into the world of home improvement, one encounters the humble clapboard—a hero of interior design, lending a rustic yet refined touch to any room. Today, we delve into the nuanced art of fastening lining to kleimers, unravelling the mystery behind this essential element of construction and design. Ready your toolkit and let’s embark on this hands-on journey of wood and nails, where precision meets aesthetics for a finish that’s both durable and delightful.

Understanding Kleimers: The Unsung Heroes of Woodwork

Interestingly, when you wander through the alleys of woodwork and renovation, kleimers might not earn a mention in the glossy brochures, yet their function cannot be overstated. These tiny metal clips are the champions in the unseen battles of construction, ensuring the lining stays exactly where it should. They lock wood panels effortlessly into place without tarnishing the surface. Best part? They leave little to no marks—truly a craftsman’s dream.

But where does one begin with kleimers? The question resonates with many a DIY renegade and seasoned professional alike. As the wise say, the journey of a thousand panels begins with a single clip. The first step is understanding which type of kleimer suits your project, a task often underestimated in its importance. Size matters, as does flexibility.

In the world of woodwork, mistakes are as abundant as sawdust. Opt for a kleimer too rigid, and you risk cracking the wood upon installation. Choose one too flexible, and the panel might slip. Balancing these elements is fundamental to achieving sleek, aesthetic results. Remember, perfection lies in the details even in the subtle art of fastening lining to kleimers.

With the right choice in hand, embark on laying the groundwork—choosing the appropriate kleimer is akin to a painter selecting a palette. It can make or break the masterpiece. Precision, friends, is the canvas on which we paint our wooden dreams.

The Step-by-Step Guide to Flawless Installation

Thinking about where to start might seem daunting, but fear not. As practice shows, a well-conceived plan breeds success. Let’s break down the installation into digestible steps:

- Select your wood: Is it oak for robustness or cedar for finesse?

- Measure twice, cut once: Ensure nothing less than precision

- Place your kleimers: Every 40cm usually does the trick

- Secure with nails: Choose ones that complement your kleimers

The overall goal is not simply attachment but creating a clean, seamless look that speaks volumes. This meticulous approach is akin to crafting a tailored suit; every pleat and seam is a testament to artistry.

A contractor often notices that *out-of-sight, out-of-mind* holds especially true here. Hidden within the shadows, kleimers quietly ensure the integrity of visible, polished surfaces. Like a symphony, they work unnoticed yet make all the difference.

The hidden strength of an installation lies in the attention to unseen details—timeless advice for both novices and seasoned renovators alike.

Durability Meets Aesthetic: The Ultimate Balancing Act

While kleimers might be the unseen enforcers of the lining world, aesthetics should dictate the visible aspects of your wood finish. This blending of functionality with visual harmony can transform a living space from mundane to marvelous.

Now consider this, what makes a wood finish truly stand out? It’s an evocative question with practical implications. Take the placement for instance. Finished panels that conform seamlessly with natural lines and room lighting create not just a room, but an experience.

Interestingly, blending tones and textures is an art in itself. A light wood paired against a darker trim can create a striking contrast, bringing depth to the finish. On the opposite side of the spectrum, uniformity can exude calm and coherence.

Ultimately, the goal is to create a living space that tells a story—a testament of craftsmanship where each panel sings its silent tune. It’s in these little episodes of creativity where a world of difference is made.

Common Pitfalls and How to Navigate Them

Even seasoned experts falter at times; the road to perfection is paved with learning. Let’s touch on a few familiar bumps one might encounter.

- Neglecting climate change: Wood warps, reacts, and breathes. Allow space for expansion.

- Underestimating wear and tear: Foot traffic, curious pets, energetic playtime.

- Overlooking insulation: Wood, especially in humid climates, adapts unwillingly.

- Ignoring alignment: A crooked line speaks louder than words.

- Forgoing regular maintenance: Time, like tide, waits for no one.

Knowing what could possibly go wrong often empowers one to preempt these issues before a single nail is driven home. This calls for a keen eye and an habit of regular inspections.

If there’s something builders understand, it’s that every undertaking from roofing to additional elements for the roof and facade requires anticipatory measures. Owning the blueprint is only part of the journey; execution in real time demands intuition and adaptability.

Contractors often notice that the best building efforts anticipate the unpredictable—nature, wear, human ingenuity.

Employing the Right Techniques for Exceptional Results

Moving beyond basics, those looking to push the boundaries of craftsmanship should consider finesse techniques. Here, we conjure a treasure trove of time-honored strategies and tips.

- Using pneumatic tools for even pressure application.

- Selecting stainless screws to combat rust in damp environments.

- Adopting staggered patterns for added visual intrigue.

- Central ventilation to manage interior temperature.

These advanced techniques offer a lifeline when aiming for superior finishing. Never shy from innovation, even when tradition promises reliability. Creativity is the pulse of design, keeping workspaces vibrant and evocative.

And when it comes to mastering gypsum plaster for exterior work, remember that even walls speak—their language is design. The secrets of longevity hinge on embracing both established practices and emerging trends. They tell a unified story where each element complements the next.

Case Study: A Small Project Turned Remarkable

Stories carry wisdom in every field; they offer insights not found in manuals. Jason, a passionate home renovator from Ohio, embarked on a modest project of lining his cottage retreat. Armed with research and sheer will, he set out to craft perfection from plainness.

Yet, the project soon turned ambitious. Jason began experimenting, setting kleimer-installed panels at varying heights to mimic the undulating waves of a lakeside vista. Observers marveled at the metamorphosis.

His efforts highlighted a simple paradox—complexity emerged from simplicity. By simply shifting perspectives and unleashing creativity, Jason turned a tiny project into a feast for the eyes.

As his endeavor beautifully illustrates, sometimes venturing beyond the manual yields astounding results. Such tales inspire both the hesitant novice and the weathered craftsman. They push boundaries, help nurture creativity, and write fresh chapters in the book of design.

Surprising facts include that those who explore outside formulas often conceive the most exceptional spaces, reminding us that constraints can indeed foster creativity.

The Benefits of Proper Clapboard Installation

In the world of woodwork, correct installation serves as the foundation for both structural integrity and aesthetics. Properly installed clapboard offers benefits beyond beauty—insulation, durability, home value—all receive a substantial boost.

- Aesthetically pleasing visual appeal.

- Long-term savings in repair costs.

- Enhanced environmental efficiency.

- Increased property value with timeless allure.

Every well-placed clapboard becomes part of a greater story—a home’s architecture, heritage, personality. Skilled hands, ready tools, and an enthusiastic mindset bring dreams closer to reality.

To explore more creative solutions, consider bath lining solutions and find a fresh palette for various spaces. They frame the architectural poetry inhabiting us all, waiting patiently to be realized.

As insightful projects like Jason’s reflect, wood paneling is but the tip of the creative iceberg. Embrace collaboration, invite personal flair, and revel in the joy of crafting spaces that reflect individual character. Creativity knows no boundaries; it thrives on imagination.

Table of Common Tools for Clapboard and Kleimer Installation

While we’ve covered many nuances, the physical process revolves around the right tools. Here’s a quick table to ensure a seamless experience:

| Tool | Purpose | Advantages | Suggestions |

|---|---|---|---|

| Hammer | Panelizing | Versatile, accessible | Ideal for initial installations |

| Nail Gun | Speed | Fast, efficient | Use for large-scale projects |

| Saw | Cutting | Precision | Choose based on wood type |

| Kleimer Pliers | Fastening | Secure grip | For kleimer adjustments |

| Level | Alignment | Ensure precision | Critical for visual symmetry |

Setting forth equipped ensures not just productivity, but mastery. Tools transform a construction dream into a tangible haven. Every nook and cranny reflects their embrace, ultimately yielding areas that make life, well, another level of delightful.

Conclusion: Fastening Lining to Kleimers with Flair

As our journey down the wooden path concludes, may this endeavor empower your aspirations. Fastening lining to kleimers whispers practice in your bones, focus in your hand. Each plank installed becomes more than simply a slat of wood. It’s part of a living tapestry, an illustration of patience and passion.

Remember, installations are gateways to transcendent experiences. From the smallest row of clapboard, aligned with purpose, grows a world of beauty and strength. So carry the essence of this craft wherever you go—be it shingle roofing in Los Angeles or cozy rural huts.

In the end, our aspirations meet life along the grain’s natural lines. Embrace them, carve your path, and let the journey of construction invariably echo within your creative spirit.

FAQ

What are kleimers and how are they used in fastening lining?

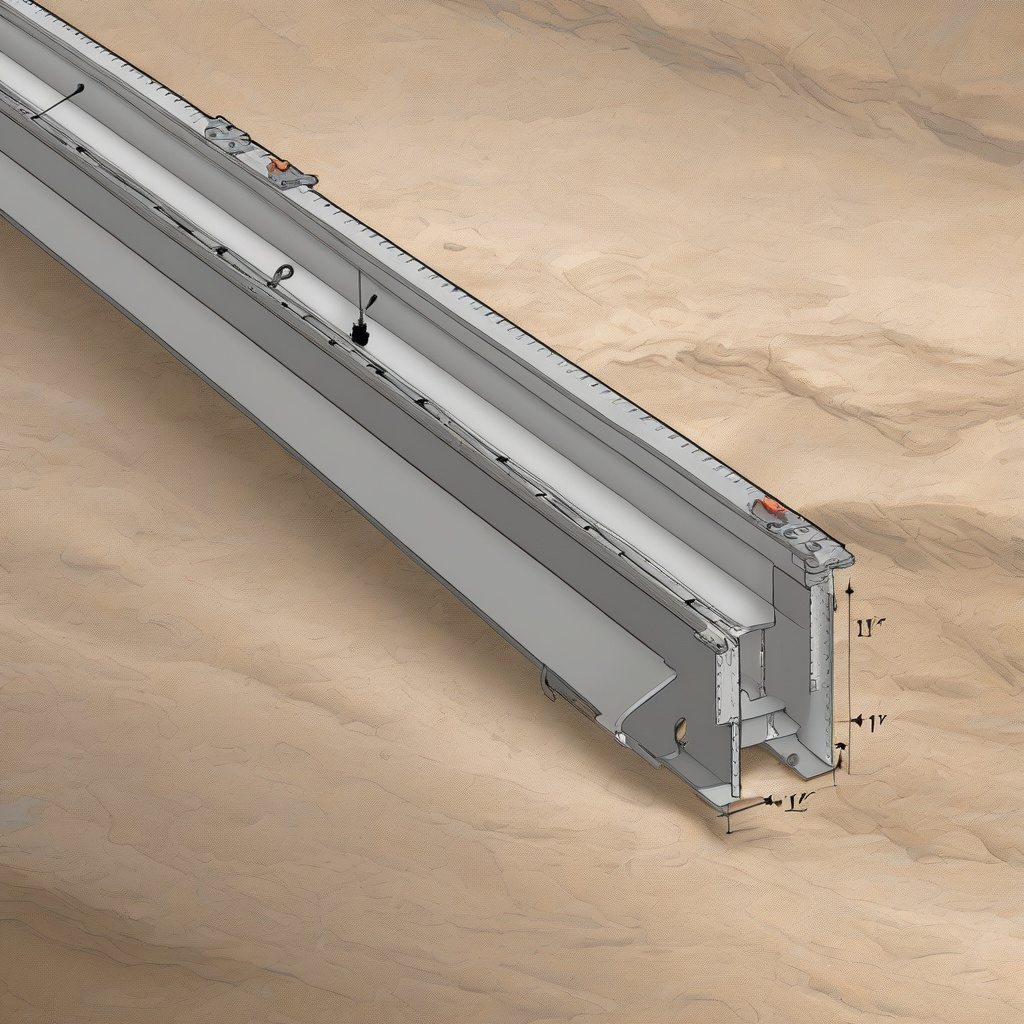

Kleimers are metal clips used to securely fasten lining materials to a surface or substructure. When installing wall or ceiling linings, kleimers are a popular choice due to their simplicity and reliability in ensuring the lining is evenly and securely attached. The metal clip is designed to fit snugly over a protrusion or edge on the lining material, locking it into place without the need for screws or nails through the material itself, thereby preserving its integrity and appearance. The strength and durability of kleimers provide high-quality results, as they offer a hidden fastening solution that enhances the aesthetic finish of the lining. Installation typically involves placing the kleimers at regular intervals along the substructure, ensuring that the lining is evenly supported and secured.

What are the benefits of using kleimers compared to traditional fastening methods?

Using kleimers for fastening lining offers several advantages over traditional methods such as nails or screws. Firstly, kleimers provide a more aesthetically pleasing finish since there are no visible fasteners on the surface of the lining, allowing the natural beauty and design of the material to shine through without interruptions. Secondly, kleimers offer increased reliability; they reduce the risk of the lining material splitting or cracking, which can occur when nailing or screwing through the material. This aspect ensures a longer lifespan for the installation. Furthermore, kleimers are versatile and can be used with various types of lining materials, including wood and PVC. This adaptability makes them a valuable tool for many projects. Lastly, kleimers facilitate easier installation, often requiring less skill and experience than traditional methods, making them an efficient option for both professionals and DIY enthusiasts.

How do I ensure the quality of installation when using kleimers?

Ensuring quality when installing lining with kleimers involves a few key steps. First, it’s crucial to select the right type and size of kleimer for your specific lining material to ensure a secure fit. Check the manufacturer’s guidelines for recommendations on kleimer spacing and selection. Prior to installation, inspect the underlying structure to confirm it’s level, as an uneven surface can lead to poor adhesion and alignment issues. During installation, maintain consistent spacing between kleimers, following the intended pattern to provide even support across the entire lining. It’s also important to use the appropriate tools to avoid damaging the kleimers or the lining. Lastly, take the time to regularly review your progress, ensuring each piece of the lining is securely fastened and aligns with adjacent pieces, which contributes to a high-quality, seamless finish. Paying attention to these details will enhance both the durability and visual appeal of your installation.

Can kleimers be used with different types of lining materials, and what should be considered for each?

Kleimers are highly adaptable and can be used with a variety of lining materials, including wood, PVC, and composite panels. When using kleimers with wood lining, it’s important to consider the wood’s thickness and moisture content, as these factors can affect expansion and contraction. Choosing kleimers that accommodate these properties will help maintain a snug fit. For PVC lining, ensure that the kleimers do not deform the material and that the PVC’s flexibility is taken into account during installation. With composite panels, the key is to select kleimers that can handle the panel’s density and weight, ensuring the supporting structure can manage the load as well. In each case, it’s crucial to check compatibility with the specific type of kleimer and follow manufacturer guidelines for optimal results. Proper planning and understanding of each material’s characteristics will ensure a successful and enduring installation.